Process complexity reached an all time pick

Digitalization has profoundly transformed the organization of all economic sectors, and the adaptation’s phase of organizations is still ongoing.

No one questions its benefits and its considerable contribution. Companies and the public sector have been forced to adopt new organizations, new ways of working and new information systems.

Major investments have been made in IT solutions (ERP, CRM, front-end tools, workflow, BI solutions, etc.).

Beneficial adaptations, but which also produced a level of complexity that was unprecedented until then.

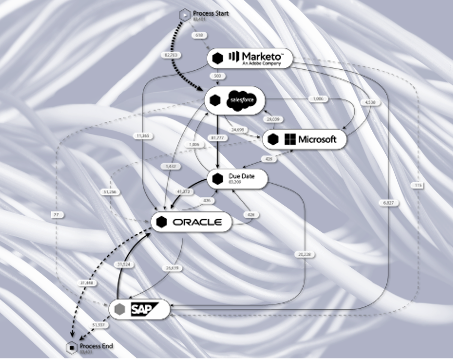

Business processes currently run through multiple information systems. For example, serving a customer today involves a myriad of applications: CRM, ERP, ticketing tools, e-mail, spreadsheets, etc. This is without counting the internal exchanges within the organization that mobilize other bricks: messaging, online chat tools…

Finally, to operate better, at cost levels that are always under pressure, and while respecting the customer promise, requires end-to-end control of operational processes. Regulatory and compliance requirements must also be ensured, without default and with an optimal level of productivity.

The search for operational excellence has reached a limit

Operational excellence initiatives have traditionally been conducted on a small scale (improving a process or a fraction of it) or in a top-down approach that struggles to produce tangible and lasting operational effects.

Most of the time, these logics go through multiple steps: information gathering and modeling of existing processes, identification of inefficiencies, modeling of target processes, improvement projects, …

Experience shows that these approaches are time-consuming and costly and produce only a fraction of the improvement needed or desired..

They come up against limits :

- a subjective and partial vision of the processes: it is based on the knowledge of a few or even their feelings. The gaps in the execution of the processes are not all known or their impacts poorly estimated,

- a discrepancy between the actions in the field, the level of management and the strategic objectives,

- a return on investment that is often questioned due to high project costs and a value contribution that is not always demonstrated,

- a growing difficulty in orchestrating continuous improvement at scale.

The methods and tools used until now are no longer able to meet these new challenges. Organizations need to make a shift to the technology made possible by artificial intelligence and machine learning. Exploiting the wealth of data generated by their information systems to derive operational value is now possible thanks to process mining.

Process Mining, a game changer to deliver value

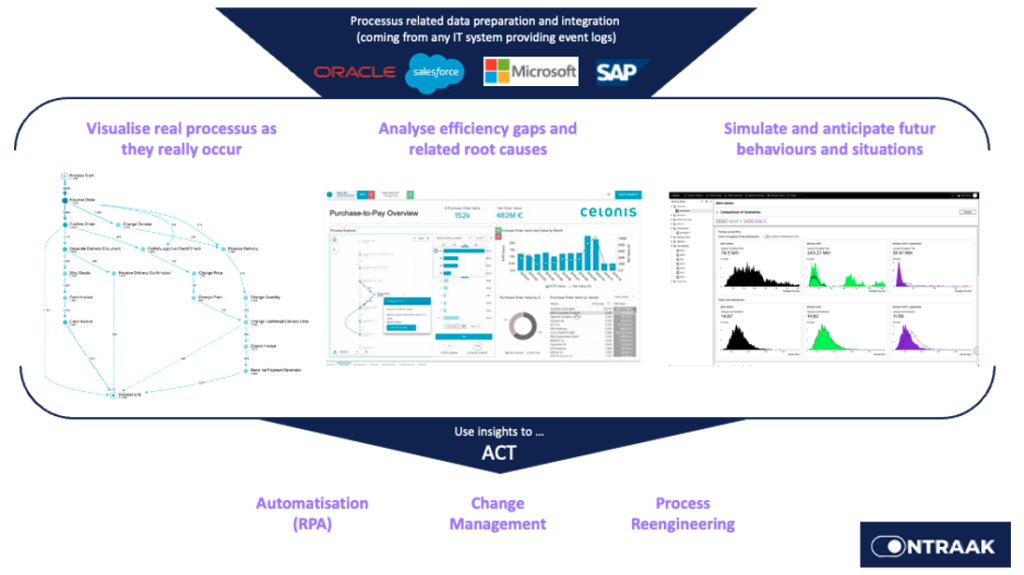

What is process mining? The main idea is to use the huge mass of data produced by information systems to obtain an exhaustive knowledge of the execution of processes. Coupled with data science, it allows to conduct diagnostics and to simulate future behaviors.

Process mining is Data Science in action.

Will van der Aalst, pope of the process mining

In concrete terms, the exhaustive representation of real processes, combined with powerful machine learning functions, helps to make an accelerated diagnosis of deviations and their impact on the performance indicators specific to each business.

This diagnostic phase, produced in a few days or weeks depending on the complexity of the information system, enables the selection of improvement actions in a “quick wins” logic.

Process mining enables this type of initiative to be approached through operational reality. By using data from the execution of processes (the digital footprint), the approach avoids the subjectivity and high costs observed in this type of project.

Actions to improve efficiency can therefore be precisely targeted on the identified difficulties. This can take the form of team training, process improvement, or the implementation of automation solutions thanks to RPA.

This tool-based and innovative approach to implementing operational performance allows us to achieve results quickly; in just a few weeks.

A new operational dynamic

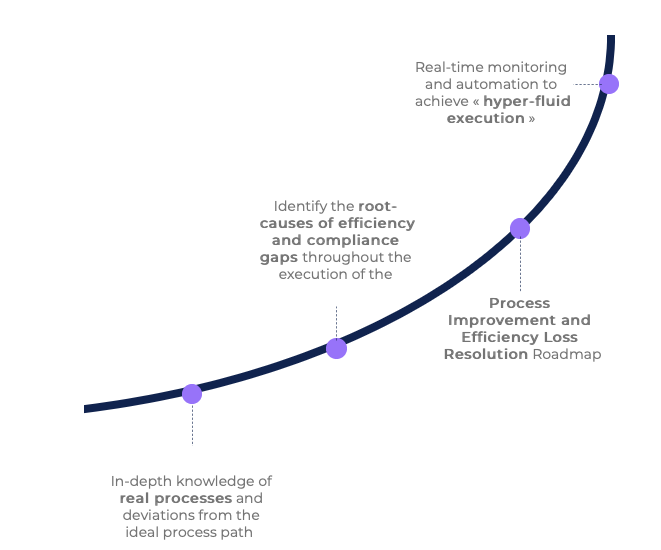

Beyond the first quick results that we are able to produce, this approach helps to instill a new dynamic of continuous improvement within the company.

Beyond these first results, this approach helps to instill a new dynamic of continuous improvement. Some businesses or sectors have difficulty establishing and maintaining a continuous improvement culture. This is made possible by extending the approach to other processes and other areas. As the indicators are produced in real time on the basis of the processes in question, any subsequent deterioration is visible

Experience shows that the best way to achieve this is to integrate into the organization a Center of Excellence in charge of the various initiatives aimed at increased operational performance:

- The identification and preparation of the necessary data,

- The knowledge of the processes through the use of process mining,

- Identification and implementation of improvement actions (process reengineering, change management, RPA, …)

- Managing continuous improvement on a daily basis and over time.

« Hyper Fluid Execution » as a goal

The end state of our approach is to enable organizations to achieve “hyper-fluid execution“.

In concrete terms, this means that the organization has a precise knowledge of the operational processes and is able to identify, anticipate and deal with deviations from the ideal execution.

This new approach to operational excellence is based on a few key axes:

- A granular approach based on the level of operational execution of processes,

- An approach capable of delivering quick wins and scaling up,

- Data-driven decisions based on operational reality and not on subjective perception or interpretation,

- Strategic dashboards based on operational reality that do not require major investments in data consolidation,

- Orchestration at scale for process improvement and automation,

- Better global coordination to leverage skills and technologies

Thanks to new technologies such as process mining, machine learning and artificial intelligence, we are able to deliver on this promise with visible results within weeks.